In the 1830’s, cranes were able to lift their own weight. Today, cranes can lift 10 times their own weight. How? Innovation. Not only through better design, but advancement in high strength steel and fabrication processes.

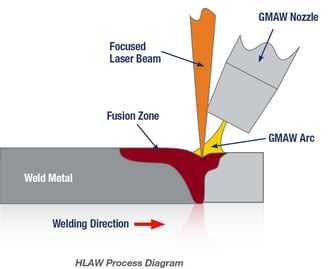

Hybrid laser Arc Welding (HLAW) is a new welding technology with unmatched precision and speed. HLAW welding offers many benefits to crane manufacturers; broken down into three simple categories.

Weight Reduction

HLAW provides weight reduction in the final product by using a fraction of the weld wire and eliminating the need for flux.

Time Saving

HLAW saves time on projects in a variety of ways. Typical Submerged Arc Welding (SAW) requires a weld on both the inside and outside of the boom, or with the addition of a backing bar. A hybrid laser allows 100% penetration welding from a single side;a backing bar is unneeded.

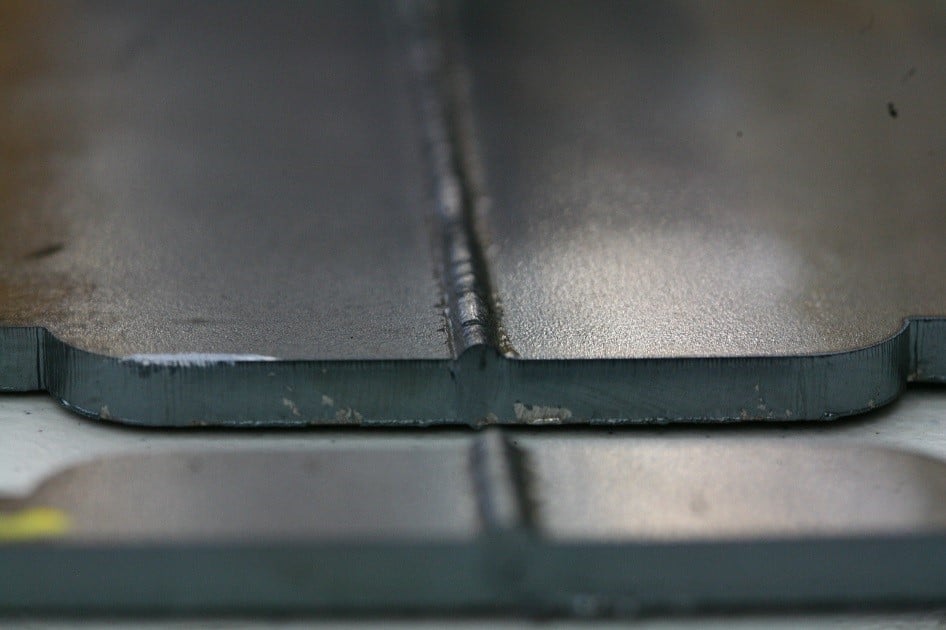

Traditional welding methods also require the base metal to be prepared with a bevel prior to welding. HLAW technology incorporates a simple butt joint. This allows booms to be welded together with fewer passes. Production hours are reduced.

Risk of deformation is reduced with the use of an HLAW machine as the precision and speed of welding limits the size of the heat-affected-zone.

The greatest benefit of HLAW is sheer speed. The welding speed of a hybrid laser system is 300 to 400% faster than the traditional SAW process.

Design

The best attributes of SAW and MIG welding are combined in an HLAW system. A near total lack of distortion lowers the need for rework after welding. The smaller heat-affected-zone in comparison to SAW also benefits the health of the material; less alteration of the properties and microstructure of the base metal is minimized.

AT&F’s investment into HLAW technology has led to the design of one of the largest hybrid laser systems in the world. Partnering with many of the leaders of the crane industry, we offer HLAW capabilities at a scale of 6m x 18m. Our weld engineering team are practiced experts in the setup and execution of HLAW projects. For more information on our Hybrid Laser Welding and what we can do for you, click below.

How to Choose a Welding Method

How to Choose a Welding Method